Shredders - RDF (Refuse Derived Fuel) Series

The future is hidden in waste : Specialists to the front !

Intelligent waste disposal - for many companies an ever increasingly important factor, as efficient disposal methods are in demand more than ever before.

Of great importance here is the processing of waste into substitute fuels namely

Refuse Derived Fuel (RDF).

WEIMA shredding solutions achieve the decisive pre-requisites to get your RDF production running, with tailor-made shredding technology for plant concepts that are oriented to the future. With leading competence based on decades of experience - more than 20,000 shredding solutions have been so far realised worldwide by WEIMA.

You have the requirements. We have the right solution.

It does not matter which type of waste you process, whether industrial, mixed building industry waste, bulk or household waste, whether production scrap, non-cellulose waste from paper-making, paper, wood, carpets or plastics : you get the best out of it with WEIMA. This is due to a specific solution adapted to your production requirements. You will be well equipped to face up to the increasingly tough market conditions. WEIMA shredding technoloty delivers the highest RDF quality and provides you with first class sales opportunities at customers such as power stations and cement producers.

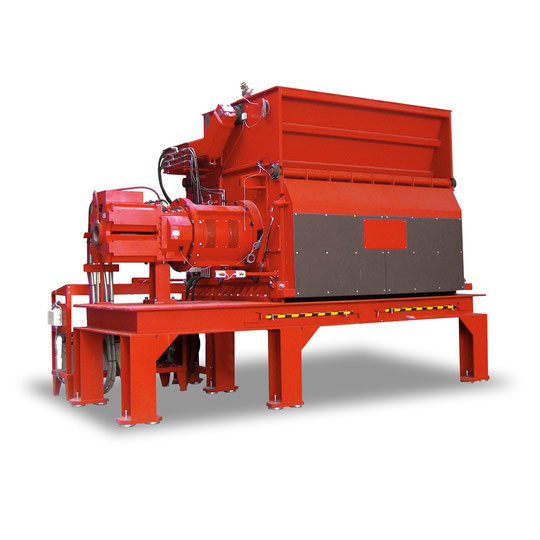

Overview of EcoLine

> rough secondary shredder for any type of waste

> insensitive to contaminated material

> ideal for multi-stage processing with high throughput

> feeding via wheel loader or gripper or after pre-shredder

> available with high performance HDW drive (hydraulic drive) for the toughest material

requirements and highest possible throughput

> can also be used as single-stage equipment,

in the event that the RDF customer provides pre-sorted material.

EcoLine range WEL 2000/600 WEL 2500/600

Rotor working width (mm) : 2,000 2,500

Rotor diameter (mm) : 600 600

Hydraulic drive (kW) : 132 160

Rotor speed (rpm) : 80 ~ 150

Blade type/size (mm) : 60 x 60 / 80 x 80

Number of blades : 46 / 115 58 / 145

Sieve perforation (mm) : 30 ~ 100

Throughput * (kg/h) : 2,000~6,000 3,000~8,000

Weight (approx.) (kg) : 20,000 22,000

* depending on the material and particle size

Overview of PowerLine

> highly efficient universal shredding solution for a wide range of input material

> flexible, as it can be used in single or multi-stage processing

> particle sizes of 30~100 mm achievable

> multi-stage processing :

operation as a secondary shredder with continuous feeding of input material

> single stage processing :

direct feeding via wheel loader or gripper

> available with the extremely high performance CDW drive (compact drive)

for the toughest requirements

PowerLine range WPL 2000/800 WPL 2500/800 WPL 3000/800

Rotor working width (mm) : 2,000 2,500 3,000

Rotor diameter (mm) : 800 800 800

Performance (kW) : 259 259 / 390 390

Rotor speed (rpm) : 100 ~ 140

Blade type/size ** (mm) : reversible crown 80 x 80

Number of blades : 69 87 108

Sieve perforation (mm) : 30 ~ 100

Throughput * (kg/h) : 3,000 ~ 8,000 4,000 ~ 12,000 5,000 ~ 15,000

Weight (approx.) (kg) : 25,000 30,000 35,000

* depending on the material and particle size

** other blade sizes and shapes possible

Overview of FineCut

> high performance secondary shredder for multi-stage processing

> shreds pre-sorted or pre-shredded material with high throughput

> continuous material input via conveyor belt feeding

> particule sizes of 15~80 mm achievable

> the right machine to produce the best RDF quality for power stations

and the cement industry

FineCut range WFC 2000/800 WFC 2500/800

Rotor working width (mm) : 2,000 2,500

Rotor diameter (mm) : 800 800

Performance (kW) : 200 315

Rotor speed (rpm) : 160 ~ 320

Blade type/size (mm) : reversible plate 172 x 57

Number of blades : 66 70

Sieve perforation (mm) : 15~ 80

Throughput * (kg/h) : 3,000 ~ 8,000 5,000 ~ 12,000

Weight (approx.) (kg) : 25,000 30,000

* depending on the material and particle size

Recycling equipment

Recycling equipment