Styrofoam Briquetting Presses

Styrofoam (EPS) is an ideal packaging material. The problem, however, is the transport and disposal. A large volume and low weight requires a high transport and storage requirements. A fully loaded truck e.g. has only a transport weight of 800 kg - which is only about 3% of the actual truck carrying capacity !

Strautmann Briquetting StyroPress® is spefifically designed for the compression of EPS and reduces the volume by up to 98% !

Here, the density of the material is increased from about 15 kg/m³ up to

700 kg/m³ !

With an compressed volume of EPS, storage space is greatly reduced !

Also saving of fuel for transportation, drastically reducing CO2 emissions !

Advantages of StyroPress®

* Fully automatic compaction system

- after filling in the material it will be shreddered and carried into the

integrated buffer and into the press chamber.

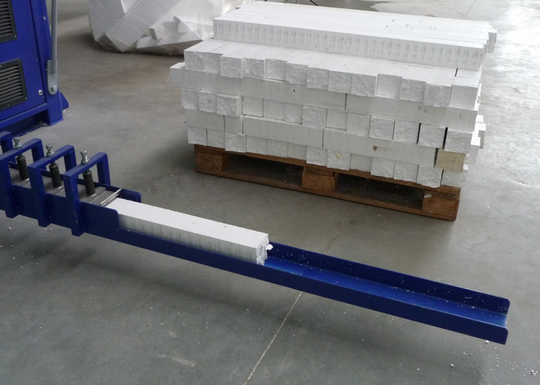

- the compacted briquettes are continuously pushed out into the discharging

system and can be removed there for storage in any appropriate ways

(bag, box, pallet, etc ..)

* Volume reduction up to 98%

- high pressing force up to 250 kN (approx. 25 ton).

- compression achievement adjustable.

* Briquetting without additives

- Confident processing.

- Genuine valuable materials.

* High briquette density up to 700 kg/m³

- fully utilise container/truck with load of 24 ton.

* High performance

- integrated shredder with max. 100 kg hourly throughput

(depending on material).

- press performance max. 30 kg/h (depending on material).

- no material warming.

- press can work continuously for 24 hours, 7 days a week.

* Universal applicable

- compact concept and dimensions.

- low space required, approx. 5m².

- suitable for EPS, XPS and PU any density.

- plug and play-installation with 32 A socket.

* Large feed opening

- easy material feeding due to large feeding opening of 1,200 x 500 mm,

located at a practical height (~1,485 mm).

* Continuous feeding

- feeding any time during the continuous operation possible.

- feeding by conveyors or suction system possible.

* High ease of use

- control by Siemsns.

- automatic operation, shredder tray can be pulled out for

maintenance / service.

- low noise due to encapsulated machine concept, max. 78 dB(A) at idle.

* Specification

- Briquette dimension : approx. 84 x 92 mm, length variable.

- Electricity supply : 400 V 50 Hz 12 kW

- Machine dimension : (L x W x H) 3,500 x 2,030 x 2,110 mm (with shredder).

- Machine weight : 2,300 kg

* Options / Accessories :

- Buffer extendable up to a silo.

- Table for pre-sorting of the material.

- Conveyor belts for continuous feeding available.

- Wing-Resolver for the integration of external processes.

- Shredder unit can be left out (depending on the raw material).

- Discharging tunnel available, fitting to all disposing systems.

Recycling equipment

Recycling equipment